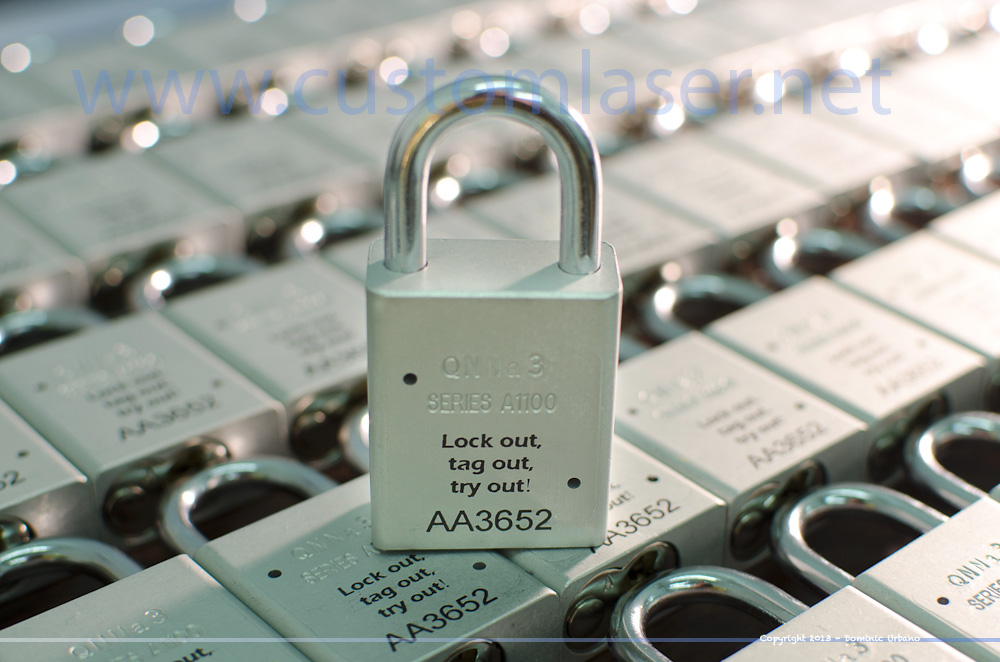

Laser marking identification on locks and tags. LOTO… safety locks ensure industrial safety.

Industrial safety requires highly durable and reliable LOTO lock identification. Laser marking does the job best!

OSHA requirements state that LOTO locks and tags be identified with durable and clear printing. Laser marking is provides the perfect solution for ensuring that your LOTO locks and keys are permanently identified. A seemingly small part of a LOTO program, clear and permanent LOTO lock and tag identification helps ensure worker safety and unnecessary job delays.

OSHA LOTO Proceedures 1910.147

“Tagout devices shall be constructed and printed so that exposure to weather conditions or wet and damp locations will not cause the tag to deteriorate or the message on the tag to become illegible.” “Identifiable. Lockout devices and tagout devices shall indicate the identity of the employee applying the device(s).”

I just completed a custom industrial laser marking job for one of my long term clients. In need of a quick turnaround my client needed 1000 LOTO locks and 2000 stainless steel identification tags. A few years ago the same client had me serialize over 6000 LOTO locks, tags, and lock boxes. It is an industrial laser marking job that illustrates how important high quality permanent identification marking can be.

For a number of years I worked as a safety coordinator for an oil refinery. LOTO (Lock Out / Tag Out) was the key to ensuring that industrial equipment that had been made safe for maintenance or repair remained that way. Isolating and securing high energy systems ensures worker safety. It is a straight forward system, that when properly implemented, gives every worker the ability to secure even the most complex systems or machinery with a single lock.

Clear and permanent identification of LOTO locks is is a key element of a LOTO program. In large scale industrial maintenance jobs or during refinery ‘turn-around’ there may be thousands of locks being used to secure individual and overlapping systems. A single lock with missing or unreadable identification marking could result in compromised safety and substantial monetary loss. Between the lost man hours… potential compromise to worker safety… or even delayed start up… something as seemingly simple as how the lock is marked and identified becomes very important.

A LOTO lock may need to remain in the field for a number months or even for years. Long term construction projects, decommissioned equipment, redesigned systems… any number of reasons that a lock may end up needing to withstand long exposure to the weather and the potentially harsh industrial environment. Permanent and clear laser marking becomes a valuable element in a quality LOTO program. The OSHA lock out tag out procedures require clear and durable identification of the locks and tags used in a LOTO safety program. Laser engraving provides high resolution permanent identification of for LOTO locks and tags.